Ukushiswa kwe-boron carbide nge-plasma: Intuthuko "yobuchwepheshe obumnyama" enguqukweni ekushisweni kwendabuko.

Emkhakheni wesayensi yezinto ezibonakalayo,i-boron carbide (B4C), eyaziwa ngokuthi “idayimane elimnyama” ngenxa yobunzima bayo obuphezulu, ukuminyana okuphansi, ukumelana nokuguguleka, kanye namandla okumunca i-neutron, isetshenziswa kabanzi emikhakheni ephezulu njengezikhali ezingangeni zinhlamvu, imboni yenuzi, kanye nezindiza. Kodwa-ke, izinqubo zendabuko zokusila (njengokusila okungenangcindezi kanye nokusila okucindezelayo okushisayo) zibhekene nezinselele ezifana namazinga okushisa aphezulu okusila, izikhathi ezinde zokusila, kanye nokuqoqwa okulula kokusanhlamvu, okunciphisa ukuthuthuka okuqhubekayo ekusebenzeni kwe-boron carbide. Eminyakeni yamuva nje, ubuchwepheshe be-spark plasma sintering (SPS), obunokushisa okuphansi, isivinini esisheshayo, kanye nokusebenza kahle okuphezulu, bube yindawo yocwaningo olushisayo lwe-boron carbide, bushintsha imingcele yokusetshenziswa kwale nto eqinile.

I. Ubuchwepheshe be-SPS: Ipharadayimu Entsha Eguqukayo Yokuthungula

Ubuchwepheshe be-SPS bufinyelela ukuminyana okusheshayo kwe-boron carbide ngomphumela wokubambisana wamanje oshukumayo, ingcindezi yomshini, kanye nensimu yokushisa. Isimiso sayo esiyinhloko sikulokhu:

Ukusebenza kwe-plasma: Ugesi ovunguzayo ukhiqiza i-plasma eshisa kakhulu ngokushesha ezikhaleni eziphakathi kwama-particle, ususa ama-oxide angaphezulu futhi ukhuthaze ukusabalala kwama-athomu.

Ukushisa kwama-Joule kanye ne-gradient yokushisa: Ugesi ukhiqiza ukushisa kwama-Joule ngesikhunta se-graphite, futhi izinga lokushisa likhuphuka ngokushesha (kufika ku-600℃/min), okwenza i-gradient yokushisa esheshisa ukuqina futhi ivimbele ukukhula kokusanhlamvu.

Ukusabalalisa Okusizwa Yinsimu Kagesi: Insimu kagesi yehlisa amandla okusebenza kwe-sintering, okwenza i-boron carbide ifinyelele ukuminyana okuphezulu (>95%) ku-1700-2100℃, okungaphansi kuka-300-500℃ kunenqubo evamile.

Uma kuqhathaniswa nokushiswa kwendabuko, i-boron carbide elungiselelwe yi-SPS inezinhlamvu ezincane (isikali se-nano kuya ku-micron) kanye nezakhiwo ezingcono kakhulu zemishini. Isibonelo, ku-1600℃ kanye ne-300MPa high pressure, ukuqina kokuqhekeka kwe-boron carbide elungiselelwe yi-SPS kukhushulwa ku-5.56MPa・m¹/², futhi ukuqina okuguquguqukayo kukhushulwa kakhulu.

II. Ukuthuthuka Kwezobuchwepheshe: Igxathu Elibalulekile Kusukela Elabhorethri Kuya Ekuthuthukisweni Kwezimboni

1. Ukuthuthukiswa Kwamapharamitha kanye Nokulawulwa Kwesakhiwo Esincane

Ukuhambisana Kokushisa Nokucindezela: Ucwaningo luthole ukuthi emazingeni okushisa aphansi (1700-2000℃), ukushelela komngcele wezinhlayiya kuholela ekuqineni, kuyilapho emazingeni okushisa aphezulu (>2000℃), ukunyuka kokususwa kwesakhiwo kuyanda. Ngokulawula ngokunembile izinga lokushisa kanye nokucindezela, usayizi wezinhlamvu ungalawulwa ngokunembile kusukela ku-4μm kuya esikalini se-nanometer.

Ukusetshenziswa Okusha Kwezinsiza Zokuhlikihla: Ukwengeza izithasiselo ezifana ne-Al, i-SiC, kanye ne-graphene kungenza ngcono ukusebenza. Isibonelo, i-B4C/SiC/Al multiphase ceramics ene-1.5% graphene (GPLs) ikhombisa ukwanda okungu-25.6% kokuqina kokuqhekeka kanye nokwanda okungu-99% kwamandla okugoba.

2. Ukwenziwa kwezinto ezisezingeni elifanele ngesinyathelo esisodwa

Ithimba le-Napo Materials lifinyelele, okokuqala ngqa, ukushiswa kwezinto ze-B4C/Al ezihlelwe ngendlela yokusebenza kusetshenziswa ubuchwepheshe be-SPS ngesinyathelo esisodwa. Lezi zinto zifinyelela ekushintsheni kwe-gradient kusuka ku-B4C emsulwa (ubulukhuni obungu-32 GPa) kuya ku-Al emsulwa (ubulukhuni obungu-1 GPa), zixazulula ngempumelelo izinkinga zomehluko omkhulu wamaphuzu okuncibilika kanye nokwakheka okulula kwezigaba zokungcola ezinqubweni zendabuko, zinikeza imibono emisha yezikhali ezingangeni zinhlamvu kanye nezinto ezihlanganisiwe zokushisa okuphezulu.

3. Ukuphumelela Kokusebenza Ezindaweni Ezibucayi

Embonini yenuzi, izifutho ze-neutron ze-B4C ezilungiselelwe yi-SPS zithola ubumsulwa obungu-99.9%, zibonisa ukumelana okuhle kakhulu nemisebe, futhi zinezindleko zokulahla imfucuza eziyingxenye eyodwa kwezinhlanu kuphela zezinto zendabuko ezisekelwe ku-cadmium. Embonini yezindiza, izinto ezihlanganisiwe ze-boron carbide/aluminium zinciphisa isisindo samapuleti okuvikela ahamba phambili enjinini ye-turbofan ngo-40% futhi zithuthukisa ukusebenza kahle kukaphethiloli ngo-2.3%.

III. Amathemba Emboni: Ulwandle Olusha Oluluhlaza okwesibhakabhaka Emakethe Yama-Trillion Dollar

1. Izicelo ziyachuma kuzo zonke izinkambu.

Imboni Yezokuvikela Nezempi: Indiza yezokuthutha ye-Osprey yezempi yase-US isebenzisa izikhali ze-B4C ezihlanganisiwe, ezinciphisa isisindo ngo-40% futhi zinikeze isivikelo esingcono kunezikhali zensimbi zendabuko.

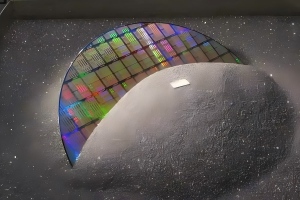

Ama-semiconductor kanye nama-elekthronikhi: Iphutha le-Boron carbide wafer stage flatness < 1μm, lihlangabezana nezidingo zokunemba okuphezulu kakhulu zemishini ye-EUV lithography. Ubuchwepheshe be-sintering obuphansi be-Zhihe New Materials bunciphisa izinga lokushisa le-sintering le-B4C libe ngu-1950℃, okwenza ukusetshenziswa kwalo kusebenze ensimini ye-semiconductor polishing pad.

Amandla Amasha Nokuvikelwa Kwemvelo: Ama-nozzle e-boron carbide andisa isikhathi sokuphila kwemishini yokuqhuma kwesihlabathi enomfutho ophezulu kusukela ezinyangeni ezi-3 kuya eminyakeni emi-2, okunciphisa izindleko zokulungisa ngo-80%. Ukusetshenziswa kwawo emandleni enuzi, amaseli elanga, kanye neminye imikhakha nakho kukhula ngokushesha.

2. Usayizi Wemakethe kanye Nezinzuzo Zenqubomgomo

Imakethe yomhlaba wonke ye-boron carbide kulindeleke ukuthi ikhule isuka ku-$180 million ngo-2025 iye ku-$320 million ngo-2030, okumele i-CAGR engu-9.5%. Njengomkhiqizi omkhulu kunabo bonke emhlabeni, i-China ithatha isikhundla esiphambili embonini ngokusekelwa kwenqubomgomo kanye nokuthuthuka kwezobuchwepheshe.

Ubuchwepheshe be-spark plasma sintering (SPCS) buhola izinto ze-boron carbide kusukela elabhorethri kuya ekuthuthukisweni kwezimboni. Ukusebenza kwayo okuphezulu kobulukhuni, ukuzinza kokushisa, kanye nokumuncwa kwe-neutron kunikeza izixazululo eziphazamisayo zokuzivikela, amandla, kanye ne-elekthronikhi. Ngokuthuthuka kobuchwepheshe kanye nokusekelwa kwenqubomgomo, i-boron carbide, le "dayimane elimnyama," ngokungangabazeki izokhanya kwezinye izinhlelo zokusebenza, ibe enye yezinto ezibalulekile eziqhuba intuthuko yobuchwepheshe babantu.