Ukusikwa kwe-boron carbide ngeplasma: Impumelelo "yobuchwepheshe obumnyama" obutsha ekusikweni kwendabuko.

Kwicandelo lesayensi yezinto eziphathekayo,i-boron carbide (B4C), eyaziwa ngokuba yi-"black diamond" ngenxa yobunzima bayo obuphezulu, uxinano oluphantsi, ukumelana nokuguguleka, kunye namandla okufunxa i-neutron, isetyenziswa kakhulu kwiindawo eziphezulu ezifana nezixhobo ezikhusela iimbumbulu, ishishini lenyukliya, kunye neenqwelo-moya. Nangona kunjalo, iinkqubo zemveli zokufunxa (ezifana nokufunxa okungenaxinzelelo kunye nokufunxa okutshisayo) zijongene nemingeni efana namaqondo obushushu aphezulu okufunxa, amaxesha amade okufunxa, kunye nokuqoqwa kweenkozo okulula, okuthintela ukuphuculwa okungakumbi ekusebenzeni kwe-boron carbide. Kwiminyaka yakutshanje, itekhnoloji yokufunxa i-spark plasma (SPS), enobushushu bayo obuphantsi, isantya esikhawulezayo, kunye nokusebenza kakuhle, iye yaba yindawo yophando olushushu lwe-boron carbide, iphinda ibumbe imida yokusetyenziswa kwesi sixhobo siqinileyo.

I. Itekhnoloji ye-SPS: Indlela entsha yokuguqula izinto

Itekhnoloji ye-SPS ifikelela ekuxineni ngokukhawuleza kwe-boron carbide ngokusebenzisa isiphumo sokusebenzisana kwe-pulsed current, uxinzelelo loomatshini, kunye nentsimi yobushushu. Umgaqo wayo oyintloko ulapha:

Ukusebenza kwePlasma: Umsinga otyhalwayo uvelisa iplasma yobushushu obuphezulu ngokukhawuleza kwiindawo eziphakathi kwamaqhekeza, isusa ii-oxides zomphezulu kwaye ikhuthaza ukusasazeka kweeathomu.

Ubushushu beJoule kunye ne-gradient yobushushu: Umbane uvelisa ubushushu beJoule nge-graphite mold, kwaye ubushushu bunyuka ngokukhawuleza (ukuya kuthi ga kwi-600℃/min), okwenza i-gradient yobushushu ekhawulezisa uxinano kwaye ithintele ukukhula kweenkozo.

Ukusasazwa Okuncediswa Yintsimi Yombane: Intsimi yombane yehlisa amandla okusebenza kwe-sintering, ivumela i-boron carbide ukuba ifikelele kuxinano oluphezulu (>95%) kwi-1700-2100℃, oluphantsi ngama-300-500℃ kunenkqubo yesiqhelo.

Xa kuthelekiswa nokusila kwendabuko, i-boron carbide elungiselelwe yi-SPS ineenkozo ezincinci (isikali se-nano ukuya kwi-micron) kunye neempawu zoomatshini eziphezulu. Umzekelo, kwi-1600℃ kunye ne-300MPa uxinzelelo oluphezulu, ukuqina kokuqhekeka kwe-boron carbide elungiselelwe yi-SPS kunyuswa ukuya kwi-5.56MPa・m¹/², kwaye ukuqina okuguquguqukayo kuphuculwe kakhulu.

II. Inkqubela phambili kwezobuchwepheshe: Inqanaba eliPhambili ukusuka kwiLebhu ukuya kwiMveliso

1. Ukwenziwa ngcono kweeParameter kunye noLawulo lweMicrostructure

Ubushushu kunye noXinzelelo: Uphando lufumanise ukuba kumaqondo obushushu aphantsi (1700-2000℃), ukutyibilika komda wamasuntswana ngokuyintloko kukhokelela ekuxinaneni, ngelixa kumaqondo obushushu aphezulu (>2000℃), ukunyuka kokusasazeka kweendawo zomoya kukona kuphambili. Ngokulawula ngokuchanekileyo isantya sobushushu kunye noxinzelelo, ubungakanani bengqolowa bunokulawulwa ngokuchanekileyo ukusuka kwi-4μm ukuya kwisikali se-nanometer.

Ukusetyenziswa Okutsha Kwezixhobo Zokuhlikihla: Ukongeza izongezo ezifana ne-Al, i-SiC, kunye ne-graphene kunokuphucula ukusebenza ngakumbi. Umzekelo, ii-ceramics ze-B4C/SiC/Al ezine-graphene eyi-1.5% (ii-GPL) zibonisa ukonyuka kwe-25.6% ekuqineni kokuqhekeka kunye nokonyuka kwe-99% kumandla okugoba.

2. Ukwenziwa kwezinto ezisemgangathweni okusebenza ngenyathelo elinye

Iqela leNapo Materials lifikelele, okokuqala ngqa, ekutshiseni izinto zeB4C/Al ngendlela yokusebenza ngokwezinga elinye kusetyenziswa itekhnoloji yeSPS. Ezi zinto zifikelela kutshintsho lwe-gradient ukusuka kwi-B4C ecocekileyo (ubulukhuni obuyi-32 GPa) ukuya kwi-Al ecocekileyo (ubulukhuni obuyi-1 GPa), zisombulula ngempumelelo iingxaki zomahluko omkhulu wamanqaku okunyibilika kunye nokwakheka okulula kwamanqanaba okungcola kwiinkqubo zendabuko, zibonelela ngeengcinga ezintsha zezixhobo ezikhusela iimbumbulu kunye nezixhobo ezidityanisiweyo zokuqhuba ubushushu obuphezulu.

3. Ukuphumelela Kokusebenza Kwiimeko Ezinzima

Kwishishini lenyukliya, ii-B4C neutron absorbers ezilungiselelwe yi-SPS zifikelela kubumsulwa be-99.9%, zibonisa ukumelana okuhle kakhulu nemisebe, kwaye zineendleko zokulahla inkunkuma ezimalunga nesinye kwisihlanu kuphela sezinto zemveli ezisekwe kwi-cadmium. Kwishishini leenqwelo-moya, izinto ezidityanisiweyo ze-boron carbide/aluminium zinciphisa ubunzima beepleyiti zokukhusela eziphambili zenjini ye-turbofan ngama-40% kwaye ziphucula ukusebenza kakuhle kwepetroli nge-2.3%.

III. Amathemba oShishino: Ulwandle Olutsha Oluluhlaza okwesibhakabhaka kwiMarike yeTrillion-Dollar

1. Izicelo ziyachuma kuzo zonke iinkalo.

Ushishino Lokhuselo Nomkhosi: Inqwelo-moya yomkhosi wase-US i-Osprey isebenzisa izixhobo ze-B4C ezidityanisiweyo, ezinciphisa ubunzima ngama-40% kwaye zibonelela ngokhuseleko olungcono kunezixhobo zentsimbi zemveli.

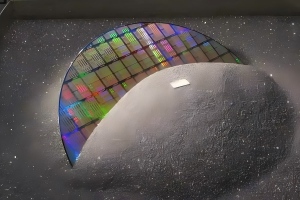

IiSemiconductors kunye nee-Electronics: Impazamo ye-Boron carbide wafer stage flatness < 1μm, ihlangabezana neemfuno ezichanekileyo kakhulu zoomatshini be-lithography be-EUV. Itekhnoloji ye-sintering yobushushu obuphantsi yeZhihe New Materials yehlisa ubushushu be-sintering be-B4C ukuya kwi-1950℃, nto leyo eqhuba ukusetyenziswa kwayo kwicandelo le-semiconductor polishing pad.

Amandla Amatsha kunye noKhuseleko lokusingqongileyo: Ii-nozzles ze-boron carbide zandisa ubomi bezixhobo zokuqhumisa isanti ezinoxinzelelo oluphezulu ukusuka kwiinyanga ezi-3 ukuya kwiminyaka emi-2, zinciphisa iindleko zokugcina ngo-80%. Ukusetyenziswa kwazo kumandla enyukliya, iiseli zelanga, kunye nezinye iindawo nako kukhula ngokukhawuleza.

2. Ubungakanani beMarike kunye neZabelo zeMigaqo-nkqubo

Imarike yehlabathi ye-boron carbide kulindeleke ukuba ikhule ukusuka kwi-180 yezigidi zeerandi ngo-2025 ukuya kwi-320 yezigidi zeerandi ngo-2030, nto leyo emele i-CAGR ye-9.5%. Njengomvelisi omkhulu kwihlabathi, iTshayina ithatha indawo ephambili kweli shishini ngenkxaso yemigaqo-nkqubo kunye nophuhliso lwetekhnoloji.

Itekhnoloji ye-spark plasma sintering (SPCS) ikhokela izixhobo ze-boron carbide ukusuka kwilebhu ukuya kwimizi-mveliso. Ukusebenza kwayo okuphezulu kobulukhuni, ukuzinza kobushushu, kunye nokufunxwa kwe-neutron kubonelela ngezisombululo eziphazamisayo zokuzikhusela, amandla, kunye ne-elektroniki. Ngophuhliso lwetekhnoloji kunye nenkxaso yemigaqo-nkqubo, i-boron carbide, le "dayimani emnyama," ngokungathandabuzekiyo iya kuqaqamba kwizicelo ezininzi, ibe yenye yezinto eziphambili eziqhuba inkqubela phambili yetekhnoloji yoluntu.