ʻO ka sintering plasma Spark o ka boron carbide: He holomua "ʻenehana ʻeleʻele" kipi i ka sintering kuʻuna.

Ma ke kahua o ka ʻepekema mea,boron carbide (B4C), i ʻike ʻia ʻo "daimana ʻeleʻele" ma muli o kona paʻakikī kiʻekiʻe, ka haʻahaʻa haʻahaʻa, ke kū'ē ʻana i ka ʻaʻahu, a me ka hiki ke komo i ka neutron, ua hoʻohana nui ʻia ma nā kahua kiʻekiʻe e like me ke kapa kila pale pōkā, ka ʻoihana nukelea, a me ka aerospace. Eia nō naʻe, ke kū nei nā kaʻina hana sintering kuʻuna (e like me ka sintering pressureless a me ka sintering kaomi wela) i nā pilikia e like me ke kiʻekiʻe o ka mahana sintering, nā manawa sintering lōʻihi, a me ka maʻalahi o ka coarsening grain, e kaupalena ana i nā hoʻomaikaʻi hou aʻe i ka hana boron carbide. I nā makahiki i hala iho nei, ua lilo ka ʻenehana spark plasma sintering (SPS), me kona mahana haʻahaʻa, ka wikiwiki wikiwiki, a me ka pono kiʻekiʻe, i wahi noiʻi wela no ka boron carbide, e hoʻololi hou ana i nā palena noi o kēia mea superhard.

I. ʻenehana SPS: He Paradigm Hou no ka Sintering

Hoʻokō ka ʻenehana SPS i ka densification wikiwiki o ka boron carbide ma o ka hopena synergistic o ke au pulsed, ke kaomi mechanical, a me ke kahua thermal. Aia kona kumumanaʻo nui i:

Hoʻoulu ʻana o ka plasma: Hoʻopuka ke au pulsed i ka plasma wela kiʻekiʻe koke i loko o nā hakahaka interparticle, e wehe ana i nā oxides o ka ʻili a paipai i ka hoʻolaha ʻana o ka atomic.

Ka hoʻomehana Joule a me ka gradient mahana: Hoʻopuka ke au uila i ka hoʻomehana Joule ma o ka ʻōmole graphite, a piʻi koke ka mahana (a hiki i ka 600 ℃ / min), e hana ana i kahi gradient mahana e hoʻolalelale i ka densification a kāohi i ka ulu ʻana o ka palaoa.

Hoʻolaha Kōkua ʻia e ke Kahua Uila: Hoʻohaʻahaʻa ke kahua uila i ka ikehu hoʻāla sintering, e hiki ai i ka boron carbide ke hoʻokō i ka density kiʻekiʻe (>95%) ma 1700-2100 ℃, ʻo ia hoʻi he 300-500 ℃ haʻahaʻa ma mua o ke kaʻina hana kuʻuna.

Ke hoʻohālikelike ʻia me ka sintering kuʻuna, ʻoi aku ka maikaʻi o nā hua boron carbide i hoʻomākaukau ʻia e SPS (nano a micron scale) a me nā waiwai mechanical kiʻekiʻe. No ka laʻana, ma 1600 ℃ a me 300MPa ke kaomi kiʻekiʻe, ua hoʻonui ʻia ka paʻakikī haki o ka boron carbide i hoʻomākaukau ʻia e SPS i 5.56MPa・m¹/², a ua hoʻonui nui ʻia ka paʻakikī dynamic.

II. Ka Holomua ʻenehana: Ka Lele Koʻikoʻi mai ka Hale Hana a i ka ʻOihana Hana

1. Hoʻonui ʻana i nā Palena a me ka Mana Microstructure

ʻO ka Mahana a me ke Kaomi Synergy: Ua ʻike ʻia e ka noiʻi ma nā mahana haʻahaʻa (1700-2000 ℃), ʻo ka paheʻe ʻana o ka palena o nā ʻāpana ke alakaʻi nui i ka densification, ʻoiai ma nā mahana kiʻekiʻe (>2000 ℃), ʻo ka piʻi ʻana o ka dislocation ka mea nui. Ma ka hoʻomalu pono ʻana i ka wikiwiki o ka hoʻomehana a me ke kaomi, hiki ke hoʻomalu pololei ʻia ka nui o ka palaoa mai 4μm a i ka nanometer.

Nā Hoʻohana Hou o nā Kōkua Sintering: ʻO ka hoʻohui ʻana i nā mea hoʻohui e like me Al, SiC, a me graphene hiki ke hoʻonui hou i ka hana. No ka laʻana, hōʻike nā keramika multiphase B4C/SiC/Al me 1.5% graphene (GPLs) i ka piʻi ʻana o 25.6% i ka paʻakikī o ka haki a me ka piʻi ʻana o 99% i ka ikaika flexural.

2. Hana ʻana i hoʻokahi ʻanuʻu o nā mea i hoʻokaʻawale ʻia e ka hana

Ua hoʻokō ka hui Napo Materials, no ka manawa mua, i ka sintering hoʻokahi-ʻanuʻu o nā mea B4C/Al i hoʻokaʻawale ʻia me ka hoʻohana ʻana i ka ʻenehana SPS. Hoʻokō kēia mea i kahi hoʻololi gradient mai B4C maʻemaʻe (paʻakikī 32 GPa) i Al maʻemaʻe (paʻakikī 1 GPa), e hoʻoponopono pono ana i nā pilikia o nā ʻokoʻa nui o ka heheʻe ʻana a me ka hoʻokumu maʻalahi ʻana o nā pae haumia i nā kaʻina hana kuʻuna, e hāʻawi ana i nā manaʻo hou no nā pale kaua pale bulletproof a me nā mea hui conductivity thermal kiʻekiʻe.

3. Ka holomua o ka hana ma nā wahi koʻikoʻi loa

I loko o ka ʻoihana nukelea, loaʻa i nā mea hoʻomoʻa neutron B4C i hoʻomākaukau ʻia e SPS kahi maʻemaʻe o 99.9%, hōʻike i ke kūpaʻa radiation maikaʻi loa, a he hapakolu wale nō ke kumukūʻai hoʻolei ʻōpala o nā mea kuʻuna i hoʻokumu ʻia i ka cadmium. I loko o ka ʻoihana aerospace, hoʻemi nā mea hui boron carbide/aluminum i ke kaumaha o nā papa pale alakaʻi o ka ʻenekini turbofan ma 40% a hoʻomaikaʻi i ka pono o ka wahie ma 2.3%.

III. Nā Manaʻolana ʻOihana: He Moana Polū Hou i loko o kahi Mākeke Trillion-Dollar

1. Ke ulu nui nei nā noi ma nā kahua āpau.

ʻOihana Pale Kaua a me ka Koa: Hoʻohana ka mokulele halihali Osprey o ka pūʻali koa US i ke kapa kila B4C, kahi e hoʻemi ai i ke kaumaha ma ka 40% a hāʻawi i ka palekana i ʻoi aku ka maikaʻi ma mua o ke kapa kila kuʻuna.

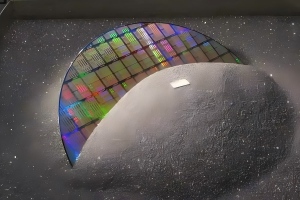

Nā Semiconductors a me nā Uila: ʻO ka hewa pālahalaha o ka pae wafer boron carbide < 1μm, e hoʻokō ana i nā koi kikoʻī kiʻekiʻe loa o nā mīkini lithography EUV. ʻO ka ʻenehana sintering haʻahaʻa haʻahaʻa o Zhihe New Materials e hōʻemi i ka mahana sintering B4C i 1950 ℃, e hoʻokele ana i kāna noi ma ke kahua pad polishing semiconductor.

Ikehu Hou a me ka Palekana Kaiapuni: Hoʻolōʻihi nā nozzles Boron carbide i ke ola o nā lako hana one-kaomi kiʻekiʻe mai 3 mahina a i 2 mau makahiki, e hōʻemi ana i nā kumukūʻai mālama ma 80%. Ke hoʻonui wikiwiki nei kā lākou noi i ka ikehu nukelea, nā cell solar, a me nā ʻoihana ʻē aʻe.

2. Ka nui o ka mākeke a me nā mahele kulekele

Ua manaʻo ʻia ka ulu ʻana o ka mākeke boron carbide honua mai $180 miliona i ka makahiki 2025 a i $320 miliona i ka makahiki 2030, e hōʻike ana i kahi CAGR o 9.5%. Ma ke ʻano he mea hana nui loa o ka honua, ke hopu nei ʻo Kina i ke kūlana alakaʻi o ka ʻoihana ma o ke kākoʻo kulekele a me nā holomua ʻenehana.

Ke alakaʻi nei ka ʻenehana Spark plasma sintering (SPCS) i nā mea boron carbide mai ka hale hana a hiki i ka ʻoihana. ʻO kāna hana kiʻekiʻe loa i ka paʻakikī, ke kūpaʻa wela, a me ka omo ʻana o ka neutron e hāʻawi i nā hopena hoʻopilikia no ka pale ʻana, ka ikehu, a me nā mea uila. Me nā holomua ʻenehana a me ke kākoʻo kulekele, ʻo ka boron carbide, kēia "daimana ʻeleʻele," e ʻālohilohi maoli nō i nā noi hou aku, e lilo i hoʻokahi o nā mea nui e hoʻokele ana i ka holomua ʻenehana kanaka.