Yin amfani da sinadarin boron carbide a cikin plasma: Wani sabon ci gaba mai ban mamaki a fannin yin amfani da sinadarin boron carbide a cikin gargajiya.

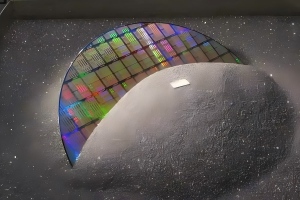

A fannin kimiyyar kayan aiki,boron carbide (B4C), wanda aka sani da "lu'u-lu'u baƙi" saboda tsananin tauri, ƙarancin yawa, juriyar lalacewa, da ƙarfin shaƙar neutron, ana amfani da shi sosai a fannoni masu ƙarfi kamar sulke mai hana harsashi, masana'antar nukiliya, da sararin samaniya. Duk da haka, hanyoyin yin sintering na gargajiya (kamar sintering mara matsi da sintering mai zafi) suna fuskantar ƙalubale kamar yanayin zafi mai yawa, tsawon lokacin sintering, da sauƙin cire hatsi, wanda ke iyakance ƙarin haɓakawa a cikin aikin boron carbide. A cikin 'yan shekarun nan, fasahar sintering plasma sintering (SPS), tare da ƙarancin zafin jiki, saurin gudu, da ingantaccen aiki, ta zama yanki mai zafi na bincike don boron carbide, tana sake fasalin iyakokin aikace-aikacen wannan kayan mai ƙarfi.

I. Fasaha ta SPS: Sabuwar Tsarin Juyin Juya Hali don Sintering

Fasahar SPS tana samun saurin nisantar boron carbide ta hanyar tasirin haɗin gwiwa na pulsed current, matsi na inji, da filin zafi. Babban ƙa'idarta ta ta'allaka ne da:

Kunna plasma: Wutar lantarki mai bugawa tana samar da plasma mai zafi sosai nan take a cikin gibin da ke tsakanin ɓangarorin biyu, tana cire oxides na saman kuma tana haɓaka yaɗuwar atomic.

Juyin Juya Halin ...

Yaɗuwar Wutar Lantarki a Fagen Wutar Lantarki: Fagen lantarki yana rage ƙarfin kunna sintering, yana ba da damar boron carbide ya cimma babban yawa (>95%) a 1700-2100℃, wanda ya fi ƙasa da tsarin gargajiya 300-500℃.

Idan aka kwatanta da na gargajiya na sintering, boron carbide da SPS ta shirya yana da ƙananan hatsi (sikelin nano zuwa micron) da kuma ingantattun kaddarorin injiniya. Misali, a matsin lamba 1600℃ da 300MPa mai ƙarfi, ƙarfin karyewar boron carbide da SPS ta shirya yana ƙaruwa zuwa 5.56MPa・m¹/², kuma ƙarfin karyewar yana ƙaruwa sosai.

II. Nasarar Fasaha: Babban Tsallakewa daga Dakin Gwaji zuwa Masana'antu

1. Inganta Sigogi da Kula da Tsarin Ƙananan Sifofi

Haɗin kai tsakanin Zafin Jiki da Matsi: Bincike ya gano cewa a yanayin zafi mai ƙarancin zafi (1700-2000℃), zamewar iyakokin barbashi galibi yana haifar da ƙaruwa, yayin da a yanayin zafi mai yawa (>2000℃), hawan katsewa yana da rinjaye. Ta hanyar daidaita saurin dumama da matsin lamba daidai, ana iya sarrafa girman hatsi daidai daga 4μm zuwa sikelin nanometer.

Amfani da Kayan Taimakon Sintering Mai Kyau: Ƙara ƙarin abubuwa kamar Al, SiC, da graphene na iya ƙara inganta aiki. Misali, yumbun B4C/SiC/Al masu matakai da yawa tare da graphene 1.5% (GPLs) suna nuna ƙaruwar taurin karyewa da kashi 25.6% da ƙaruwar ƙarfin lanƙwasawa da kashi 99%.

2. Ƙirƙirar kayan aiki masu inganci mataki ɗaya

Ƙungiyar Napo Materials ta cimma, a karon farko, yin sintering na kayan aikin B4C/Al ta hanyar amfani da fasahar SPS. Wannan kayan yana cimma sauyi mai sauƙi daga B4C mai tsarki (taushi 32 GPa) zuwa Al mai tsarki (taushi 1 GPa), tare da samun nasarar magance matsalolin manyan bambance-bambancen wuraren narkewa da kuma sauƙin samar da ƙazanta a cikin hanyoyin gargajiya, yana samar da sabbin dabaru don sulke mai hana harsashi da kayan haɗin kai mai ƙarfi.

3. Nasarar Aiki a Muhalli Masu Tsanani

A masana'antar nukiliya, masu shaƙar neutron na B4C da SPS ta shirya suna samun tsarkin kashi 99.9%, suna nuna kyakkyawan juriya ga radiation, kuma suna da kuɗin zubar da shara wanda kashi ɗaya bisa biyar ne kawai na kayan gargajiya na cadmium. A cikin masana'antar sararin samaniya, kayan haɗin boron carbide/aluminum suna rage nauyin faranti na kariya na gaba na injin turbofan da kashi 40% kuma suna inganta ingancin mai da kashi 2.3%.

III. Hasashen Masana'antu: Sabuwar Tekun Shuɗi a Kasuwar Dala Tiriliyan

1. Aikace-aikace suna bunƙasa a duk fannoni.

Masana'antar Tsaro da Soja: Jirgin saman jigilar kaya na rundunar sojin Amurka na Osprey yana amfani da sulke mai hade da B4C, wanda ke rage nauyi da kashi 40% kuma yana ba da kariya mafi kyau fiye da sulken ƙarfe na gargajiya.

Masu amfani da Semiconductor da Lantarki: Kuskuren matakin da ke tsakanin bututun Boron carbide da ƙasa da 1μm, wanda ya cika buƙatun daidaito na injunan lithography na EUV. Fasahar sintering mai ƙarancin zafin jiki ta Zhihe Sabbin Kayan Aiki ta rage zafin sintering na B4C zuwa 1950℃, wanda ke haifar da amfani da shi a filin sintering na semiconductor.

Sabuwar Makamashi da Kare Muhalli: Boron carbide nozzles yana tsawaita rayuwar kayan aikin busar da yashi mai ƙarfi daga watanni 3 zuwa shekaru 2, wanda hakan ke rage farashin gyara da kashi 80%. Amfani da su a makamashin nukiliya, ƙwayoyin hasken rana, da sauran fannoni shi ma yana faɗaɗa cikin sauri.

2. Girman Kasuwa da Rabon Manufofi

Ana hasashen cewa kasuwar boron carbide ta duniya za ta karu daga dala miliyan 180 a shekarar 2025 zuwa dala miliyan 320 a shekarar 2030, wanda ke wakiltar CAGR na 9.5%. A matsayinta na babbar mai samar da kayayyaki a duniya, kasar Sin tana karbe matsayinta na gaba a masana'antar ta hanyar tallafin manufofi da ci gaban fasaha.

Fasahar Spark plasma sintering (SPCS) tana jagorantar kayan boron carbide daga dakin gwaje-gwaje zuwa masana'antu. Ingantaccen aikinta a cikin tauri, kwanciyar hankali na zafi, da kuma shan neutron yana samar da mafita mai kawo cikas ga tsaro, makamashi, da na'urorin lantarki. Tare da ci gaban fasaha da tallafin manufofi, boron carbide, wannan "lu'u-lu'u baƙi," babu shakka zai haskaka a cikin ƙarin aikace-aikace, yana zama ɗaya daga cikin mahimman kayan da ke haifar da ci gaban fasaha na ɗan adam.