Kutulutsa boron carbide mu plasma: Kupita patsogolo kwa "ukadaulo wakuda" pakusintha kwachikhalidwe.

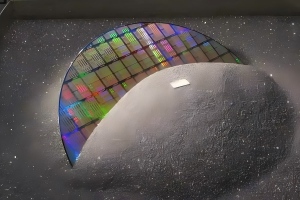

Mu gawo la sayansi ya zinthu,boron carbide (B4C), yomwe imadziwika kuti "diamondi yakuda" chifukwa cha kuuma kwake kwakukulu, kukhuthala kwake kochepa, kukana kuvala, komanso mphamvu yake yoyamwa neutron, imagwiritsidwa ntchito kwambiri m'magawo apamwamba monga zida zoteteza zipolopolo, makampani opanga zida za nyukiliya, ndi ndege. Komabe, njira zachikhalidwe zoyatsira moto (monga kuyatsira moto popanda kupanikizika komanso kuyatsa moto) zimakumana ndi zovuta monga kutentha kwambiri, nthawi yayitali yoyatsira moto, komanso kuuma kwa tirigu mosavuta, zomwe zimalepheretsa kusintha kwina pakugwira ntchito kwa boron carbide. M'zaka zaposachedwa, ukadaulo wa spark plasma sintering (SPS), wokhala ndi kutentha kochepa, kuthamanga kwake mwachangu, komanso kugwira ntchito bwino, wakhala malo ofufuzira kwambiri a boron carbide, kusinthanso malire ogwiritsira ntchito zinthuzi zolimba kwambiri.

I. Ukadaulo wa SPS: Njira Yatsopano Yosinthira Zinthu Zopangira Sintering

Ukadaulo wa SPS umakwaniritsa kukhuthala kwa boron carbide mwachangu kudzera mu mphamvu ya synergistic ya pulsed current, mechanical pressure, ndi thermal field. Mfundo yake yaikulu ndi iyi:

Kuyambitsa kwa Plasma: Mpweya wothamanga umapanga plasma yotentha kwambiri nthawi yomweyo m'mipata yapakati pa tinthu tating'onoting'ono, kuchotsa ma oxide pamwamba ndikulimbikitsa kufalikira kwa maatomu.

Kutentha kwa Joule ndi kutentha: Mphamvu yamagetsi imapanga kutentha kwa Joule kudzera mu nkhungu ya graphite, ndipo kutentha kumakwera mofulumira (mpaka 600℃/min), kupanga kutentha komwe kumathandizira kukhuthala ndikuletsa kukula kwa tirigu.

Kufalikira kwa Magetsi: Magetsi amachepetsa mphamvu yoyambitsa kuyaka, zomwe zimathandiza kuti boron carbide ifike pamlingo wapamwamba (>95%) pa 1700-2100℃, womwe ndi wotsika kwambiri kuposa njira yachikhalidwe.

Poyerekeza ndi sintering yachikhalidwe, boron carbide yokonzedwa ndi SPS ili ndi tinthu tating'onoting'ono (nano mpaka micron scale) komanso mphamvu zabwino kwambiri zamakanika. Mwachitsanzo, pa 1600℃ ndi 300MPa kuthamanga kwambiri, kulimba kwa boron carbide yokonzedwa ndi SPS kumawonjezeka kufika pa 5.56MPa・m¹/², ndipo kulimba kwamphamvu kumawonjezeka kwambiri.

II. Kupita Patsogolo kwa Ukadaulo: Kudumpha Kofunika Kwambiri Kuchokera ku Laboratory Kupita ku Industrial Development

1. Kukonza Ma Parameter ndi Kulamulira Kapangidwe Kakang'ono

Kugwirizana kwa Kutentha ndi Kupanikizika: Kafukufuku wapeza kuti kutentha kotsika (1700-2000℃), kutsetsereka kwa malire a tinthu kumabweretsa kuchulukana, pomwe kutentha kokwera (>2000℃), kukwera kwa dislocation kumakhala kwakukulu. Mwa kuwongolera bwino kutentha ndi kupanikizika, kukula kwa tirigu kumatha kulamulidwa molondola kuyambira 4μm mpaka sikelo ya nanometer.

Kugwiritsa Ntchito Zinthu Zatsopano Zothandizira Kuchepetsa Kutupa: Kuwonjezera zowonjezera monga Al, SiC, ndi graphene kungathandize kwambiri kuti zinthu zigwire bwino ntchito. Mwachitsanzo, B4C/SiC/Al multiphase ceramics yokhala ndi 1.5% graphene (GPLs) ikuwonetsa kuwonjezeka kwa 25.6% pakulimba kwa kusweka ndi kuwonjezeka kwa 99% pakulimba kwa kusinthasintha.

2. Kupanga zinthu zogwiritsidwa ntchito m'magawo amodzi

Gulu la Napo Materials lakwanitsa, koyamba, kusuntha pang'ono zinthu za B4C/Al pogwiritsa ntchito ukadaulo wa SPS. Zinthuzi zimakwaniritsa kusintha kwa gradient kuchokera ku B4C yoyera (kuuma 32 GPa) kupita ku Al yoyera (kuuma 1 GPa), kuthetsa mavuto a kusiyana kwakukulu kwa mfundo zosungunuka komanso kupanga mosavuta magawo odetsedwa m'njira zachikhalidwe, kupereka malingaliro atsopano a zida zoteteza zipolopolo ndi zinthu zophatikizana zomwe zimatenthedwa kwambiri.

3. Kupambana kwa Magwiridwe Antchito M'malo Ovuta Kwambiri

Mu makampani opanga zida za nyukiliya, zotengera ma neutron a B4C zokonzedwa ndi SPS zimakhala ndi chiyero cha 99.9%, zimalimbana bwino ndi ma radiation, ndipo zimakhala ndi ndalama zotayira zinyalala zomwe ndi gawo limodzi mwa magawo asanu okha a zinthu zachikhalidwe zopangidwa ndi cadmium. Mu makampani opanga ndege, zinthu zopangidwa ndi boron carbide/aluminium zimachepetsa kulemera kwa mbale zoteteza injini za turbofan ndi 40% ndikuwonjezera kugwiritsa ntchito bwino mafuta ndi 2.3%.

III. Ziyembekezo Zamakampani: Nyanja Yatsopano Yabuluu Mumsika Wa Madola Tiliyoni

1. Mapulogalamu akuchulukirachulukira m'magawo onse.

Chitetezo ndi Makampani Ankhondo: Ndege zonyamula anthu za Osprey za asilikali aku US zimagwiritsa ntchito zida zankhondo za B4C, zomwe zimachepetsa kulemera ndi 40% ndipo zimapereka chitetezo chapamwamba kuposa zida zankhondo zachitsulo zachikhalidwe.

Ma Semiconductor ndi Zamagetsi: Cholakwika cha Boron carbide wafer stage flatness < 1μm, chomwe chikukwaniritsa zofunikira kwambiri pamakina a EUV lithography. Ukadaulo wa Zhihe New Materials wochepetsa kutentha kwa B4C sintering umachepetsa kutentha kwa B4C kufika pa 1950℃, zomwe zimapangitsa kuti igwiritsidwe ntchito m'munda wa semiconductor polishing pad.

Mphamvu Zatsopano ndi Chitetezo cha Zachilengedwe: Ma nozzles a Boron carbide amawonjezera moyo wa zida zophulitsira mchenga zomwe zimakhala ndi mphamvu yayikulu kuchokera pa miyezi itatu mpaka zaka ziwiri, zomwe zimachepetsa ndalama zokonzera ndi 80%. Kugwiritsa ntchito kwawo mu mphamvu ya nyukiliya, maselo a dzuwa, ndi madera ena kukukulirakuliranso mwachangu.

2. Kukula kwa Msika ndi Magawidwe a Ndondomeko

Msika wapadziko lonse wa boron carbide ukuyembekezeka kukula kuchoka pa $180 miliyoni mu 2025 kufika pa $320 miliyoni mu 2030, zomwe zikuyimira CAGR ya 9.5%. Monga wopanga wamkulu kwambiri padziko lonse lapansi, China ikutenga malo otsogola mumakampaniwa kudzera mu chithandizo cha mfundo ndi kupita patsogolo kwaukadaulo.

Ukadaulo wa Spark plasma sintering (SPCS) ukutsogola zipangizo za boron carbide kuchokera ku labotale kupita ku mafakitale. Kuchita bwino kwake kolimba, kukhazikika kwa kutentha, komanso kuyamwa kwa neutron kumapereka njira zosokoneza chitetezo, mphamvu, ndi zamagetsi. Ndi kupita patsogolo kwaukadaulo ndi chithandizo cha mfundo, boron carbide, "diamondi wakuda" iyi, mosakayikira idzawala kwambiri m'magwiritsidwe ntchito ambiri, kukhala imodzi mwa zipangizo zofunika kwambiri zomwe zimayendetsa patsogolo ukadaulo wa anthu.