Ịgbasa ihe mkpofu nke boron carbide: Ihe ọhụrụ "teknụzụ ojii" mere n'ịkwasa ihe mkpofu ọdịnala.

N'ihe gbasara sayensị ihe,boron carbide (B4C), nke a maara dị ka "dayamọnd ojii" n'ihi oke ike ya, obere njupụta ya, iguzogide iyi, na ikike ịmịkọrọ neutron, a na-ejikarị ya eme ihe n'ọhịa dị elu dịka ihe agha na-egbochi mgbọ, ụlọ ọrụ nuklia, na mbara igwe. Agbanyeghị, usoro nsị ọdịnala (dị ka nsị na-enweghị nrụgide na ịpị ọkụ) na-eche ihe ịma aka dị ka okpomọkụ dị elu, oge nsị ogologo, na mkpụmkpụ ọka dị mfe, na-egbochi mmezi ndị ọzọ na arụmọrụ boron carbide. N'afọ ndị na-adịbeghị anya, teknụzụ nsị plasma (SPS), nke nwere obere okpomọkụ, ọsọ ọsọ, na arụmọrụ dị elu, aghọwo ebe nyocha na-ekpo ọkụ maka boron carbide, na-agbanwegharị ókè ojiji nke ihe a siri ike.

I. Teknụzụ SPS: Usoro Ọhụrụ Mgbanwe Maka Sintering

Teknụzụ SPS na-enweta njupụta ngwa ngwa nke boron carbide site na mmetụta synergistic nke pulsed current, mechanical pressure, na thermal field. Isi ihe dị na ya bụ:

Mmelite plasma: Ọkụ a na-amịpụta na-emepụta plasma okpomọkụ dị elu ozugbo n'ime oghere interparticle, na-ewepụ oxides dị n'elu ma na-akwalite mgbasa atomic.

Okpomọkụ na mgbanwe okpomọkụ nke Joule: Ọkụ eletrik na-emepụta okpomọkụ Joule site na ebu graphite, okpomọkụ ahụ na-arị elu ngwa ngwa (ruo 600℃/min), na-emepụta mgbanwe okpomọkụ nke na-eme ka njupụta dịkwuo ngwa ngwa ma na-egbochi uto ọka.

Mgbasa Ozi Enyere Aka n'Ọgba Eletriki: Ọgba eletriki ahụ na-ebelata ike mkpali sintering, na-eme ka boron carbide nweta njupụta dị elu (>95%) na 1700-2100℃, nke dị ala karịa usoro ọdịnala 300-500℃.

Ma e jiri ya tụnyere ihe e ji esi nri ọdịnala, boron carbide nke SPS kwadebere nwere obere mkpụrụ (nano ruo micron scale) na ihe ndị ọzọ dị mma. Dịka ọmụmaatụ, na oke nrụgide 1600℃ na 300MPa, ike mgbawa nke boron carbide nke SPS kwadebere na-abawanye ruo 5.56MPa・m¹/², ike ike na-abawanye nke ukwuu.

II. Mmepe Teknụzụ: Mbuli dị mkpa site na ụlọ nyocha gaa na mmepụta ihe

1. Nhazi Paramita na Njikwa Microstructure

Njikọta Okpomọkụ na Nrụgide: Nnyocha achọpụtala na n'okpomọkụ dị ala (1700-2000℃), mmịpụta ókè nke ihe ndị dị n'ime ya na-eduga n'ịba ụba, ebe n'okpomọkụ dị elu (>2000℃), mmụgharị nkewa na-achịkwa. Site n'ịchịkwa ọnụego okpomọkụ na nrụgide kpọmkwem, enwere ike ijikwa nha ọka nke ọma site na 4μm ruo na nha nanometer.

Ngwa ọhụrụ nke ihe enyemaka Sintering: Ịtinye ihe mgbakwunye dịka Al, SiC, na graphene nwere ike ime ka arụmọrụ dịkwuo mma. Dịka ọmụmaatụ, seramiiki B4C/SiC/Al nwere graphene 1.5% (GPLs) na-egosi mmụba 25.6% na ike mgbawa na mmụba 99% na ike ịgbatị.

2. Imepụta ihe ndị a na-arụ ọrụ nke ọma site n'otu nzọụkwụ gaa n'ọkwa dị elu

Ndị otu Napo Materials enwetala, maka oge mbụ, otu nzọụkwụ nke ihe ndị a na-arụ ọrụ nke ọma site na iji teknụzụ SPS. Ihe a na-enweta mgbanwe gradient site na B4C dị ọcha (ike 32 GPa) gaa na Al dị ọcha (ike 1 GPa), na-edozi nsogbu nke nnukwu ọdịiche ebe agbaze na nhazi dị mfe nke usoro adịghị ọcha na usoro ọdịnala, na-enye echiche ọhụrụ maka ihe agha na-anaghị agba egbe na ihe ndị mejupụtara okpomọkụ dị elu.

3. Nkwalite Arụmọrụ n'Ebe Dị Oke Mfe

N'ime ụlọ ọrụ nuklia, ihe ndị na-amịkọrọ neutron B4C nke SPS kwadebere na-enweta ịdị ọcha nke 99.9%, na-egosipụta ezigbo iguzogide radieshon, ma nwee ọnụ ahịa mkpofu ihe mkpofu nke bụ naanị otu ụzọ n'ụzọ ise nke ihe ndị e ji cadmium mee. N'ime ụlọ ọrụ ụgbọelu, ihe ndị mejupụtara boron carbide/aluminum na-ebelata ibu nke efere nchebe turbofan nke na-eduga n'ihu injin site na 40% ma na-eme ka arụmọrụ mmanụ dịkwuo mma site na 2.3%.

III. Atụmanya Ụlọ Ọrụ: Oké Osimiri Anụnụ Ọhụrụ n'Ahịa Trillion Dollar

1. Ngwa na-aga nke ọma n'akụkụ niile.

Ụlọ Ọrụ Nchebe na Ndị Agha: Ụgbọelu njem Osprey nke ndị agha US na-eji ihe agha B4C, nke na-ebelata ibu site na 40% ma na-enye nchebe karịa ihe agha ígwè ọdịnala.

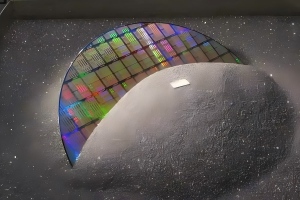

Ndị na-eduzi Semiconductor na Eletrọniki: Error Boron carbide wafer flatness ogbo < 1μm, na-emezu ihe achọrọ nke igwe lithography EUV. Teknụzụ sintering dị ala nke Zhihe New Materials na-ebelata okpomọkụ sintering B4C ruo 1950℃, na-eme ka ojiji ya na mpaghara polishing semiconductor pad.

Ike Ọhụrụ na Nchedo Gburugburu Ebe Obibi: Ihe mkpuchi Boron carbide na-agbatị ndụ nke ngwa ọrụ na-eji ájá eme ihe nke nwere nrụgide dị elu site na ọnwa atọ ruo afọ abụọ, na-ebelata ọnụ ahịa mmezi site na 80%. Ntinye ha na ike nuklia, mkpụrụ ndụ anyanwụ, na ubi ndị ọzọ na-agbasakwa ngwa ngwa.

2. Nha Ahịa na Uru Ego Atumatu

A na-atụ anya na ahịa boron carbide zuru ụwa ọnụ ga-eto site na $180 nde na 2025 ruo $320 nde na 2030, nke na-anọchite anya CAGR nke 9.5%. Dịka onye na-emepụta ihe kachasị ukwuu n'ụwa, China na-ejide ọkwa kachasị elu nke ụlọ ọrụ ahụ site na nkwado amụma na ọganihu teknụzụ.

Teknụzụ Spark plasma sintering (SPCS) na-eduga ihe ndị dị na boron carbide site na ụlọ nyocha ruo na mmepụta ihe. Arụmọrụ ya dị elu na ike, nkwụsi ike okpomọkụ, na ntinye neutron na-enye ngwọta na-akpata nsogbu maka nchekwa, ike, na ngwa eletrọnịkị. Site na ọganihu teknụzụ na nkwado amụma, boron carbide, "daịamọnd ojii" a, ga-enwu n'ọtụtụ ngwa, na-aghọ otu n'ime ihe ndị bụ isi na-akwalite ọganihu teknụzụ mmadụ.