Kev siv plasma sintering ntawm boron carbide: Kev hloov pauv "dub technology" hauv kev sintering ib txwm muaj.

Hauv kev tshawb fawb txog cov ntaub ntawv,Boron carbide (B4C), hu ua "dub pob zeb diamond" vim nws qhov nyuaj siab, qhov ceev tsawg, kev tiv thaiv hnav, thiab lub peev xwm nqus neutron, yog siv dav hauv cov teb siab xws li cov cuab yeej tiv thaiv mos txwv, kev lag luam nuclear, thiab aerospace. Txawm li cas los xij, cov txheej txheem sintering ib txwm muaj (xws li pressureless sintering thiab kub nias sintering) ntsib cov teeb meem xws li kub sintering siab, lub sijhawm sintering ntev, thiab yooj yim grain coarsening, txwv tsis pub txhim kho ntxiv hauv kev ua tau zoo ntawm boron carbide. Nyob rau hauv xyoo tas los no, spark plasma sintering (SPS) thev naus laus zis, nrog nws qhov kub qis, ceev ceev, thiab kev ua haujlwm siab, tau dhau los ua thaj chaw tshawb fawb kub rau boron carbide, rov ua dua cov ciam teb ntawm cov khoom siv superhard no.

I. SPS Technology: Ib qho Paradigm Tshiab rau Sintering

SPS thev naus laus zis ua tiav kev sib sau ua ke sai ntawm boron carbide los ntawm kev sib koom ua ke ntawm cov hluav taws xob pulsed, lub zog kho tshuab, thiab lub tshav kub. Nws lub hauv paus ntsiab lus yog:

Kev ua haujlwm ntawm cov ntshav: Cov hluav taws xob pulsed tsim cov ntshav kub tam sim ntawd hauv cov qhov sib txawv ntawm cov khoom sib xyaw, tshem tawm cov oxides ntawm qhov chaw thiab txhawb kev sib kis ntawm atomic.

Kev kub thiab qhov kub thiab txias ntawm Joule: Cov hluav taws xob tam sim no tsim Joule cua sov los ntawm cov pwm graphite, thiab qhov kub nce sai (txog li 600 ℃ / feeb), tsim cov kub thiab txias uas ua rau kom cov khoom ntom ntom thiab tiv thaiv cov noob kom loj hlob.

Kev Pab Cuam Hluav Taws Xob Los Ntawm Kev Sib Kis: Lub zog hluav taws xob txo qis lub zog ua kom sintering, ua rau boron carbide ua tiav qhov ceev siab (> 95%) ntawm 1700-2100 ℃, uas yog 300-500 ℃ qis dua li cov txheej txheem ib txwm muaj.

Piv nrog rau kev sintering ib txwm muaj, boron carbide uas SPS npaj muaj cov noob me me (nano rau micron scale) thiab cov khoom siv kho tshuab zoo dua. Piv txwv li, ntawm 1600 ℃ thiab 300MPa siab siab, qhov tawg toughness ntawm boron carbide uas SPS npaj tau nce mus txog 5.56MPa・m¹/², thiab qhov dynamic toughness tau txhim kho ntau heev.

II. Kev Txhim Kho Txog Kev Siv Tshuab: Qhov Tseem Ceeb ntawm Kev Tshawb Fawb Hauv Chaw Kuaj Mob mus rau Kev Lag Luam

1. Kev Txhim Kho Cov Txheej Txheem thiab Kev Tswj Xyuas Microstructure

Kev Sib Koom Tes Kub thiab Siab: Kev tshawb fawb tau pom tias thaum kub qis (1700-2000 ℃), qhov kev swb ntawm ciam teb ntawm cov khoom me me feem ntau ua rau muaj kev sib sau ua ke, thaum thaum kub siab (> 2000 ℃), kev nce siab ntawm qhov sib txawv yog qhov tseem ceeb. Los ntawm kev tswj hwm qhov kub thiab siab kom raug, qhov loj ntawm cov noob tuaj yeem tswj tau raws li qhov tseeb ntawm 4μm mus rau qhov ntsuas nanometer.

Cov Kev Siv Tshiab ntawm Sintering Aids: Ntxiv cov khoom ntxiv xws li Al, SiC, thiab graphene tuaj yeem ua kom zoo dua qub. Piv txwv li, B4C/SiC/Al multiphase ceramics nrog 1.5% graphene (GPLs) qhia txog kev nce 25.6% ntawm kev tawg thiab kev nce 99% ntawm kev khoov zog.

2. Kev tsim cov khoom siv uas muaj qib zoo ib kauj ruam xwb

Pab neeg Napo Materials tau ua tiav, thawj zaug, ib kauj ruam sintering ntawm B4C / Al cov ntaub ntawv qib ua haujlwm siv SPS thev naus laus zis. Cov khoom siv no ua tiav qhov kev hloov pauv gradient los ntawm B4C ntshiab (hardness 32 GPa) mus rau Al ntshiab (hardness 1 GPa), ua tiav kev daws teeb meem ntawm qhov sib txawv loj ntawm cov ntsiab lus yaj thiab yooj yim tsim cov theem tsis huv hauv cov txheej txheem ib txwm muaj, muab cov tswv yim tshiab rau cov cuab yeej tiv thaiv mos txwv thiab cov ntaub ntawv sib xyaw ua ke siab thermal conductivity.

3. Kev Ua Tau Zoo Tshaj Plaws hauv Ib puag ncig hnyav heev

Hauv kev lag luam nuclear, SPS-npaj B4C neutron absorbers ua tiav qhov huv ntawm 99.9%, ua pov thawj zoo heev tiv thaiv hluav taws xob, thiab muaj cov nqi pov tseg uas tsuas yog ib feem tsib ntawm cov khoom siv cadmium ib txwm muaj. Hauv kev lag luam aerospace, boron carbide / aluminium composite cov ntaub ntawv txo qhov hnyav ntawm turbofan engine leading-edge protection plates los ntawm 40% thiab txhim kho kev siv roj los ntawm 2.3%.

III. Kev Cia Siab Txog Kev Lag Luam: Ib Lub Hiav Txwv Xiav Tshiab hauv Kev Lag Luam Muaj Nqis Ib Trillion-Dollar

1. Cov ntawv thov tau vam meej thoob plaws txhua qhov chaw.

Kev Tiv Thaiv thiab Kev Lag Luam Tub Rog: Cov tub rog Asmeskas lub dav hlau thauj khoom Osprey siv cov cuab yeej sib xyaw ua ke B4C, uas txo qhov hnyav los ntawm 40% thiab muab kev tiv thaiv zoo dua li cov cuab yeej hlau ib txwm muaj.

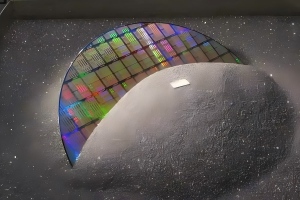

Cov Khoom Siv Semiconductors thiab Electronics: Boron carbide wafer theem flatness yuam kev < 1μm, ua tau raws li qhov xav tau ultra-high precision ntawm EUV lithography tshuab. Zhihe New Materials 'low-temperature sintering technology txo qhov kub B4C sintering mus rau 1950 ℃, tsav nws daim ntawv thov hauv semiconductor polishing pad teb.

Lub Zog Tshiab thiab Kev Tiv Thaiv Ib Puag Ncig: Cov nozzles boron carbide ntev lub neej ntawm cov khoom siv xuab zeb siab los ntawm 3 lub hlis mus rau 2 xyoos, txo cov nqi txij nkawm los ntawm 80%. Lawv daim ntawv thov hauv lub zog nuclear, lub hnub ci hlwb, thiab lwm yam teb kuj tseem nthuav dav sai.

2. Qhov Loj ntawm Kev Lag Luam thiab Cov Nyiaj Faib ntawm Txoj Cai

Kev lag luam boron carbide thoob ntiaj teb yuav loj hlob ntawm $ 180 lab hauv xyoo 2025 mus rau $ 320 lab hauv xyoo 2030, uas sawv cev rau CAGR ntawm 9.5%. Ua tus tsim khoom loj tshaj plaws hauv ntiaj teb, Tuam Tshoj tab tom txeeb txoj haujlwm ua tus thawj coj hauv kev lag luam los ntawm kev txhawb nqa txoj cai thiab kev tshawb fawb txog thev naus laus zis.

Kev siv tshuab Spark plasma sintering (SPCS) yog cov khoom siv boron carbide los ntawm chav kuaj mus rau kev lag luam. Nws qhov kev ua tau zoo tshaj plaws hauv kev tawv, kev ruaj khov thermal, thiab kev nqus neutron muab cov kev daws teeb meem rau kev tiv thaiv, lub zog, thiab hluav taws xob. Nrog rau kev nce qib ntawm thev naus laus zis thiab kev txhawb nqa txoj cai, boron carbide, qhov "pob zeb diamond dub," no yuav ci ntsa iab hauv ntau daim ntawv thov, ua ib qho ntawm cov khoom siv tseem ceeb uas tsav tsheb kev nce qib ntawm tib neeg.